Driveline Inspection & Component Location on a Mercedes

Chassis

Introduction

Welcome to Grafco Electric, your reliable source for electrical services and driveline inspections for Mercedes vehicles! In this comprehensive guide, we will walk you through the importance of driveline inspection, component location, and how it ultimately improves the performance of your Mercedes.

Why is Driveline Inspection Important?

Proper driveline inspection is crucial for maintaining the longevity and performance of your Mercedes. A driveline is a complex system consisting of various components such as the engine, transmission, driveshaft, differential, axles, and wheels. Over time, these components can wear out or become damaged, potentially leading to issues such as power loss, vibrations, and even complete driveline failure.

By performing regular driveline inspections, you can identify any potential problems early on and take necessary preventive measures. This not only ensures your safety on the road but also saves you from costly repairs in the long run.

Component Location

In order to perform a comprehensive driveline inspection, it's essential to know the location of various driveline components in your Mercedes. Let's take a detailed look:

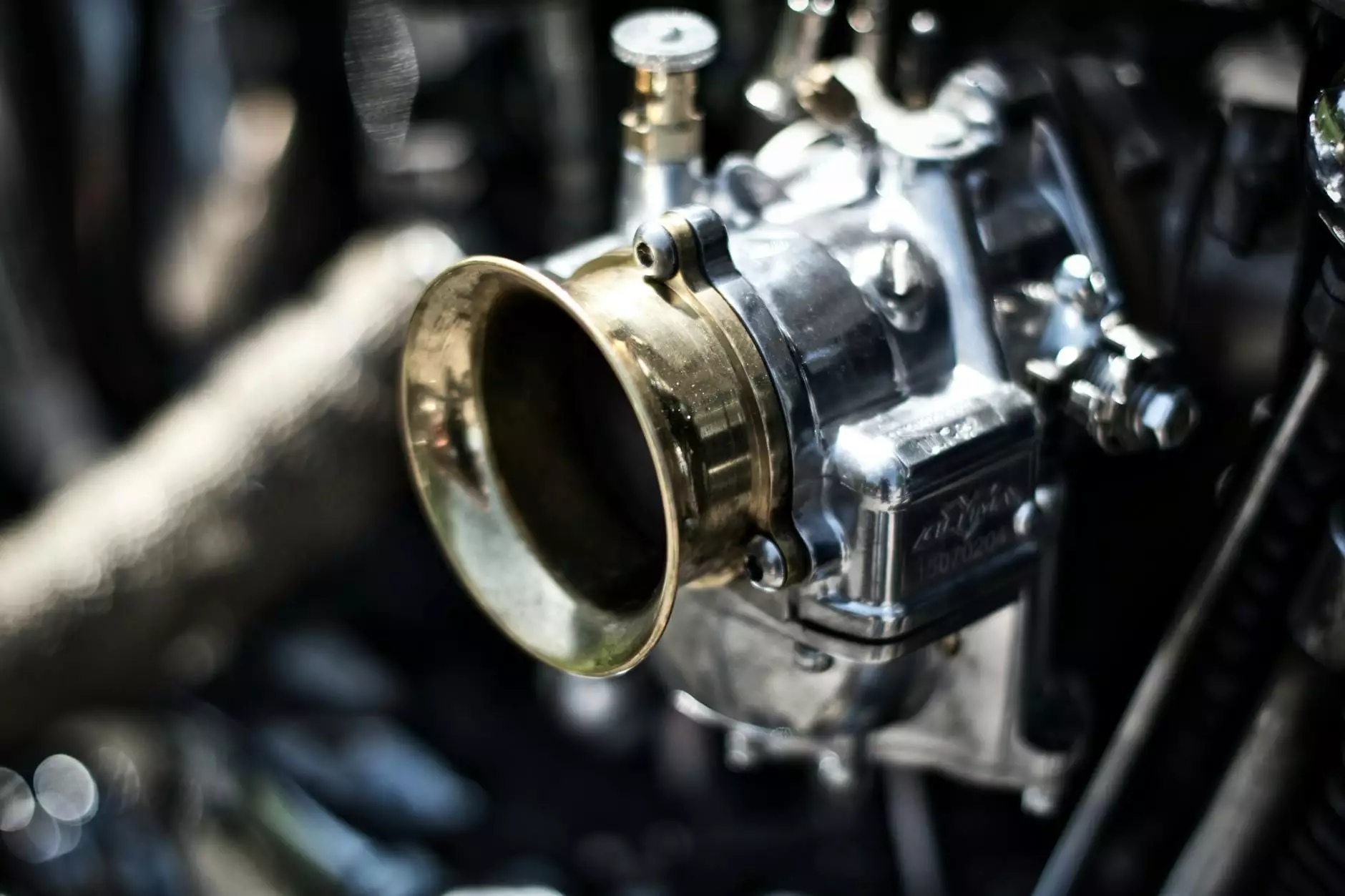

Engine

The engine is the heart of your Mercedes. It is typically located in the front part of the vehicle and connected to the transmission via the bell housing. Regular engine maintenance, including oil changes, filter replacements, and overall inspection, is vital for optimal driveline operation.

Transmission

The transmission is responsible for transferring power from the engine to the wheels. In most Mercedes models, the transmission is located towards the rear of the engine compartment. It's crucial to check the transmission fluid levels, inspect for leaks, and ensure smooth gear shifts to avoid driveline issues.

Driveshaft

The driveshaft, also known as the propeller shaft, is a rotating tube that transfers torque from the transmission to the differential. It connects the rear of the transmission to the rear differential. Inspecting the driveshaft for any signs of wear, loose connections, or imbalances is vital for a smooth and efficient driveline operation.

Differential

The differential allows the wheels to rotate at different speeds when turning corners, ensuring optimal traction and stability. In Mercedes vehicles, the differential is typically located at the rear, near the back wheels. Regular inspection of the differential fluid, seals, and gears is essential to prevent driveline problems.

Axles

Axles are responsible for delivering power from the differential to the wheels. In most Mercedes models, each wheel has its own axle shaft. It's crucial to inspect the axles for any signs of leaks, damage, or excessive play to avoid driveline malfunction.

Wheels

Lastly, the wheels are the final component of the driveline system. Check for proper tire inflation, wheel alignment, and balance to ensure optimal driveline performance and a smooth ride.

Conclusion

By understanding the importance of driveline inspection and component location on your Mercedes, you can effectively maintain your vehicle's performance and prevent any potential issues. Regular inspection of the driveline components, as explained above, will help you identify problems early on, leading to safer and more reliable drives.

At Grafco Electric, we specialize in providing top-notch driveline inspection services for Mercede